Products > Casing Scraper

-KINGWELL SUPER Unique Shape-Razor™ Scraper

-------------------------------

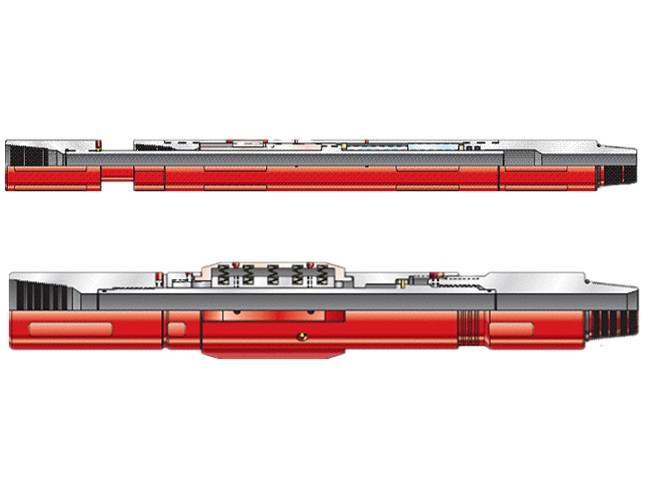

KINGWELL HD Shape-Razor™ Casing Scraper

One Specialized wellbore Cleanup Tool

Introduction

The HD Shape-Razor™ Casing Scraper consists of: a high-strength, one-piece mandrel and is designed to meet the demands of Complex wellbore cleanups. By allowing a higher RPM and weight-on-bit rating than the standard Shape-Razor device. The HD Shape-Razor Casing Scraper unit is well suited for drilling up cement accessories commonly found inside the liner or casing.

Features:

l More effective. robust and safer to use in a ll wellbore-cleanup of casing-scraping operations.

l Higher RPM and weight-on-bit rating than the standard Shape Razor

l 360°coverage, and equal cleaning force at all angles of well inclination.

l Suitable for severe environment, HTHP-compatible and is not vulnerable to chemical or acid attack.

l Available with all API and premium drill pipe connections

Application

Removes cement sheath, burrs, and pipe scale

Pre-completion wellbore clean-up

Workovers and sidetracking

Abandonment

Drilling / milling cement plugs

| DIMENSIONAL DATA | ||||||

| Nominal OD(in) | Weight (ppf) | Connection | Centralizer OD(in) |

Scraper Cage OD (in) |

ID(in) | Length (in) |

| 7.000 |

23.0-29.0 32.0-38.0 |

NC38 |

6.054 5.790 |

6.680 6.415 |

1.500 | 101.4 |

| 9.625 |

53.5-64.9 47.0-53.5 36.0-43.5 |

NC50 |

8.129 8.374 8.594 |

8.800 9.000 9.250 |

2.500 | 103.8 |

----------------

KINGWELL RIGID Shape-Razor™ Casing Scraper

One Specialized wellbore Cleanup Tool

Introduction

The RIDGE Shape-Razor™ Casing Scraper developed for use in perforated casing or liner to remove perforation burrs and to ensure the safe passage of completion equipment. Provides advanced wellbore cleanup in the post-perforating well phase, where a high degree of casing or liner ID smoothness through the perforated interval is required . Completely removes perforation burrs, preventing damage to completion equipment, including expandable screens/expandable pipe used in complex/smart completion .

Features:

l Robust enough to remove bigger and large volume burrs, cementing accessories.

l Clean by rotation and up/down pipe movement..

l Supplied with drill-pipe box up/pin-down connections .

l Available in all common casing/ liner sizes .

Application

Mainly used in perforated casing or liner to remove perforation burrs and to ensure the safe passage of completion equipment

| Length(inch) | Bore(inch) |

Casing weight PPF |

Centralizer OD inch |

Blade OD(inch) |

OD (inch) |

Connection(API) |

Max. Tensile (t) |

Max. Torque(KN.M) |

| 68 1/2 | 1 | 11.5-15 | 4 | 4 2/3 | 4 | 2 3/8REG | 65 | 25 |

| 68 1/2 | 1 1/2 | 14-17 | 4 | 4 2/3 | 4 | NC31 | 80 | 30 |

| 71 | 1 7/8 | 17-29 | 5 4/5 | 6 3/5 | 5 4/5 | NC38 | 120 | 40 |

| 71 | 1 7/8 | 36-58.4 | 8 1/4 | 9 | 8 1/4 | NC50 | 150 | 50 |

KrinBack™ Casing Brush

---------------------------

1,Description

The MATECLEAN wellbore preparation tool builds on field proven scraper, brush, and magnet technology to supply a single fit-for-purpose tool that can be utilized in standard wellbore displacement and workover applications or sold as part of the completion assembly to provide additional cleaning during installation.

The design of the MATECLEAN incorporates existing technologies from other Baker Hughes wellbore cleanup products for increased reliability and synergy. The tool is designed with large ID’s to accommodate high flow rates. The integrated tool incorporates three independent technologies into one system. The scraper section is used to remove mud or cement sheath, perforation burs, rust, scale, paraffin or similar substances from the casing inside diameter (ID). The brush section assists the scraper in removing debris from the casing ID and helps to agitate fluid during displacement applications for improved effectiveness. The magnet section collects ferrous debris from the wellbore and retrieves it to surface.

The MATECLEAN wellbore preparation tool can be used in a variety of applications, whether it be temporary wellbore cleanup service or permanent installation with downhole completion and intervention systems. In standard wellbore cleanup and displacement applications, the MATECLEAN offers a cost effective, integrated solution for cleaning the wellbore. Additionally, the tool may be run ahead of bridge plugs, whipstocks, lower completion systems, or other systems that will be temporarily or permanently installed in the wellbore. The MATECLEAN assists in cleaning debris ahead of these other products and helps to prepare the setting area, improving the system reliability. The tool’s simplistic, yet robust design makes it a cost-effective solution for a variety wellbore cleanup applications.

Applications

· Deepwater

· Remedial and stimulation

· Casing exits

· Completions

· Conventional

· Unconventional

Features and Benefits

· Brushes and scraper blades with 360 degree coverage provides high cleaning effectiveness

· Hard metal applied to scraper blade edge provides endurance and maximum service life

· Stabilizer with integrated magnets collects metal debris downhole and retrieves them to surface and provides additional centralization in deviated wellbores

· Versatile design based on existing wellbore cleanup technology incorporates multiple wellbore cleanup functions into a single tool, creating cost effective solution for both rental and saleable applications and improves system reliability

Specifications

Casing Size: 7 inch 26-32 lb/ft

Connection: 4.5 inch 12.6 lb/ft TejnarisHydril Blue Box by Pin

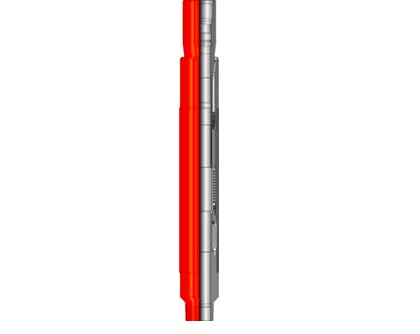

A clean well is essential prior to running expensive and sensitive completion strings or other debris sensitive equipment. Therefore removal, collection of debris and verification of debris removal are extremely important in a wellbore. These operations can be optimized by the Sharp-Razor™ Wellbore Cleaning equipment.

Sharp-Razor™ Casing Scraper is a mechanical tool for clean and polishes the casing or liner ID to remove mud solids, cement sheath, scale and perforation burrs in any wellbore.

The Sharp-Razor™ Casing Scraper can be integrated as a part of a complete

wellbore cleaning tool string used during displacement process prior to

running completion. It can be rotated and reciprocated without fear of

damage to casing or tool due to the rugged design and the fact that

it doesn’t contain external bolts that could work loose under extreme

conditions.

A Sharp-Razor™ Casing Scraper tool consists of a one-piece Body, non-rotating

Stabiliser and Scraper assembly. The main mandrel rotates through the stabiliser and Scraper assembly to avoid wear or damage to the casing during drill string rotation. The Scraper assembly is self-centralising inside the casing or liner to ensure equal cleaning at all well conditions. It’s also rough, flexible and has the force needed remove and clean 360 degrees without rotation.

The tool is suitable for HPHT wells and can withstand chemical or acid attack.

Typical applications

— Cleaning debris from wellbores in any wellbore cleanup operations

— Post perforation cleaning

— Cleaning after side track operations

— When cleaning is required in drilling operations

Features

— One piece mandrel

— Non rotating stabilizers

— Non rotating scraper sleeve

— No external nuts or bolts

— Standard drill pipe connections

— Extra Large bypass areas for eliminating flow restrictions

Benefits

— Clean 360 degrees without rotation

— Eliminates casing wear

— High strength mandrel

— Simple to run

— Multiple run possible

— Withstand drilling and milling operations

Products

+Drilling Equipment

- Casing Scraper

- balck rhino Non rotating Casing Scrappe

- RazRdillo Casing Scraper

- multiple activation autolock bypass tools

- Non-rotating wellbore casing scraper

- Wellbore Cleaning up tools

- Drill Pipe

- Downhole Motor

- KINGWELL Stabilizer-sleeve type

- Deflecting tools and mill tools

- drill bits

- Cross Coupling Cable Protector

- KINGWELL Underreamer

- Reammate Underreamer

- mill shose

- KINGWELL Raiseboring drill pipes

- Stabilizer

- future drill tools

- RGS Remote Gauge Stabilizer

- Shock Tools

- Casing and Pipe cutting equipment

- HORNET Series Drilling Tools

- Hydraulic Oscillator

- Hydraulic Thruster

- Drill Bit

- Jar Intensifier Type YJQ

- Overshot

- Full opening safety valve

- Top Drive Drilling Tools

- Hole Opener

- Drill Hydroscillator

- Lubricated Fishing Bumper Sub Type BXJ

- Drilling Jar

- Continuous Circulating Valve

- Inside Blowout Control Tools

- Multi-cycle Circulating tools

- Hydraulic Jar Type YSJ

- Drilling Accelerator Type ZJQ

- Fishing Bumper Sub Type KXJ

- Model DJQ Cable Jar

- Model ZTX Highly-Efficient Vibration Resi

- Super Fishing Jar Type CSJ

- Surface Bumper Jar Type DJ

- Surface Bumper Jar Type DX

- Two-action Drill Accelerator Type SZJQ

- Fishing Spear

- Junk Basket

- Wear Preventive Subs

- Kelly

- Heavy Weight Drill Pipe

- Drill Collar

- Magnetic Fishing Tool

- Die Collar

- Casing Scraper

- Shock Absorber

- Pup Joint

- Subs

+Rig Accessories

- KWDWS Water Cooling Eddy Current Brakes

- BOP

- Christmas Tree

- An Overview of OCTG Piping Inspection Met

- Casing and tubing

- Wire-wrapped Screen

- ASTM A53 GRADE B SEAMLESS

- flange

- EN 10217 Welded steel pipe

- Oil Country Tubular Goods (OCTG)

- ASTM A333 Grade1 Carbon Steel Pipe

- Coiled Tubing

- High Pressure Fluid Control Products

- Coupling

- API 5CT Hot Rolled Tubing Pup Joint

- Ram Type and Annular Type Blowout Prevent

- Solids Control System

- Crown Block

- F-1600HL Mud Pump

- Coiled Tubing BOP

- drilling line

- Kill Manifold and Choke Manifold

- F-2200HL Mud Pump

- Ironroughneck

- Hydraulic Disc Brake System

- Mud Hopper and Mud mixing pump

- Gate Valve

- Top Drive

- OCTG

- Butterfly Valve

- Globe Valve

- Ball Valve

- Plug Valve

- Choke Valve

- Check Valve

- Casing Hanger and Tubing Hanger

- Tubing Spool and Casing Spool

- Slip

- Tong

- Elevator

- Tubing Head

- Casing Head

- Drawworks

- High and Low Pressure Pipe Manifold

- Forgings for Flange/Valve/Shaft/Gear

- Forging for Downhole Tools

- Pipe Mould

- Die Steel/Tool Steel

- Mandrel Bar

- Rolling Mill Roll

- Corrugated roll

- Travelling Block and Hook

- Rig Swivel

- Drilling Rig Mast

- Rotary Table

- Mud Pump

- Vacuum Degasser

- Other Solid Control Equipment

- Shaker Screen

- Submersible Slurry Pump

- Shear Pump

- Mud Agitator

- Centrifugal Pump

- Decanter Centrifuge

- Desilter

- Desander

- Mud Cleaner

- Linear Motion Shale Shaker

+APR Drill Stem Testing Tools

- Rupture Disk (RD) Sampler

- Slip Joint

- Hydraulic Jar

- Shock Absorber

- Gauge Carrier

- Drain Valve

- OMNI Valve

- LPR-N Valve

- Safety Valve

- Safety Joint

- Circulating Valve

- RTTS Packer

- Super Safety Valve/Subsea Safety Valves (

- Hydro Trip Pressure Sub

- Surface Well Testing system

- APR Pressure-controlled Formation Tester

- Full-bore Compensating Pipe

- Retrievable Service Packers

- Fullbore DST string

- DST TOOLS specification

- Subsurface Control Valve (SSC) Storm Vavl

- Champ v Packer

- Storm Valve

- Tester Valve